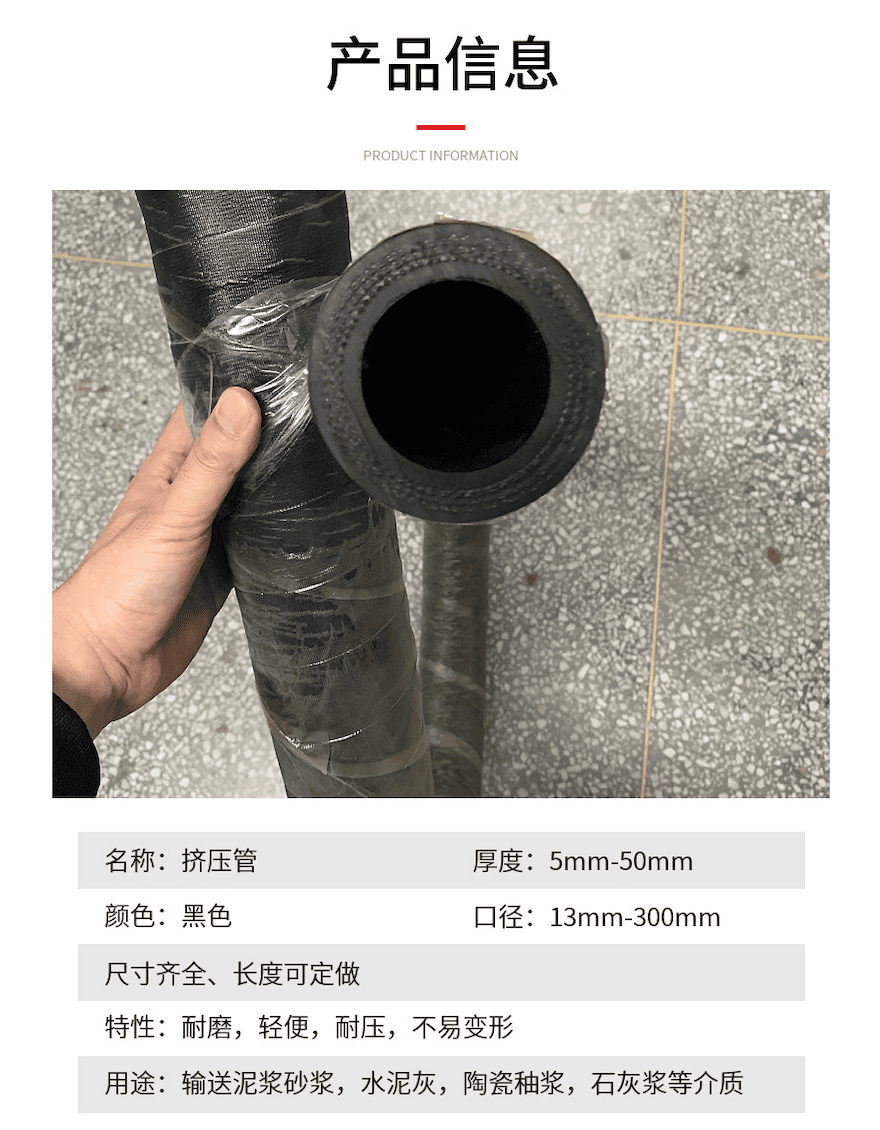

Peristaltic Pump Tubing: High-Durability, Precision Fluid Transfer Solution

Peristaltic pump tubing is widely used in laboratories, pharmaceuticals, food processing, and industrial production. With excellent chemical resistance and precise fluid transfer capabilities, it is an ideal choice for accurate fluid control.

Features and Benefits of Peristaltic Pump Tubing

1. Chemical Resistance

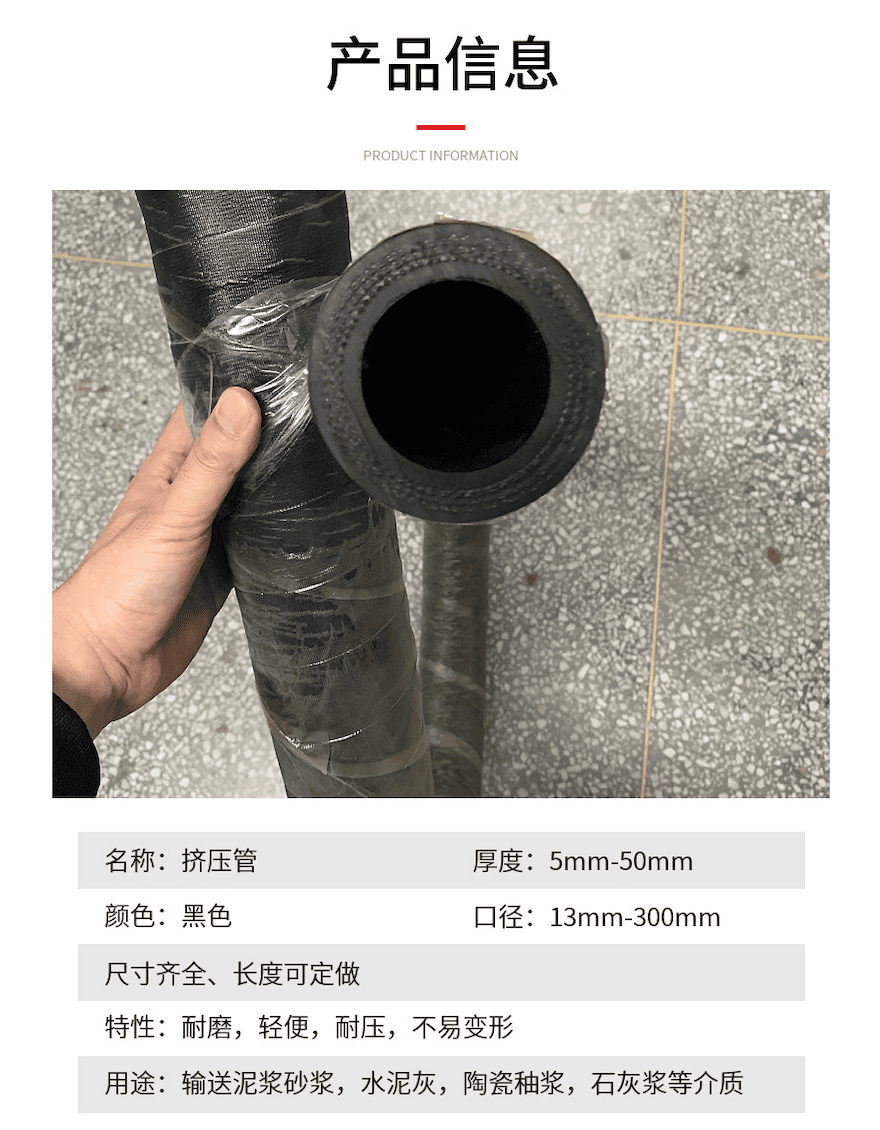

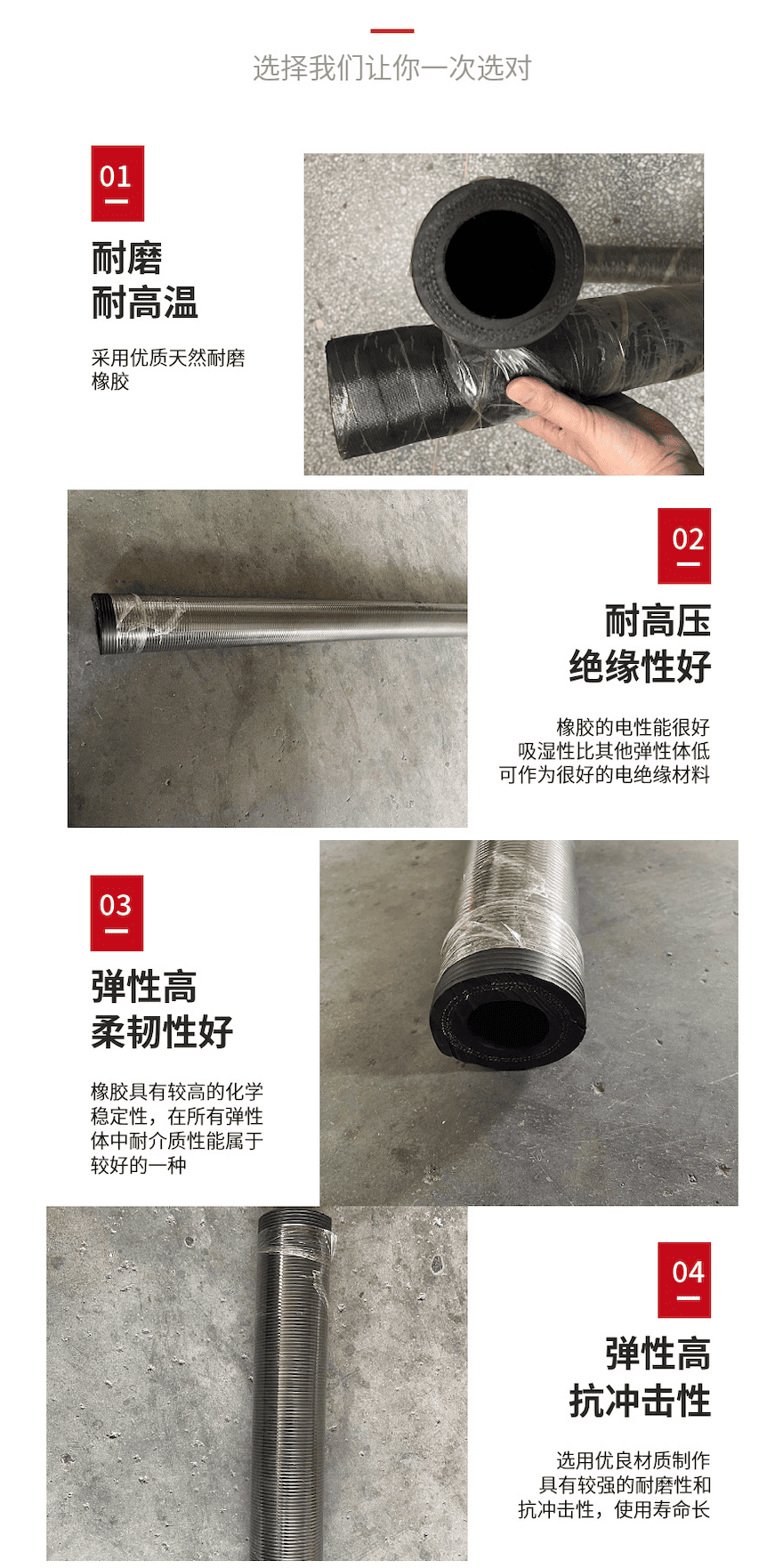

Made from high-polymer materials, it resists acids, alkalis, solvents, and various chemicals, making it suitable for laboratory and chemical industries.

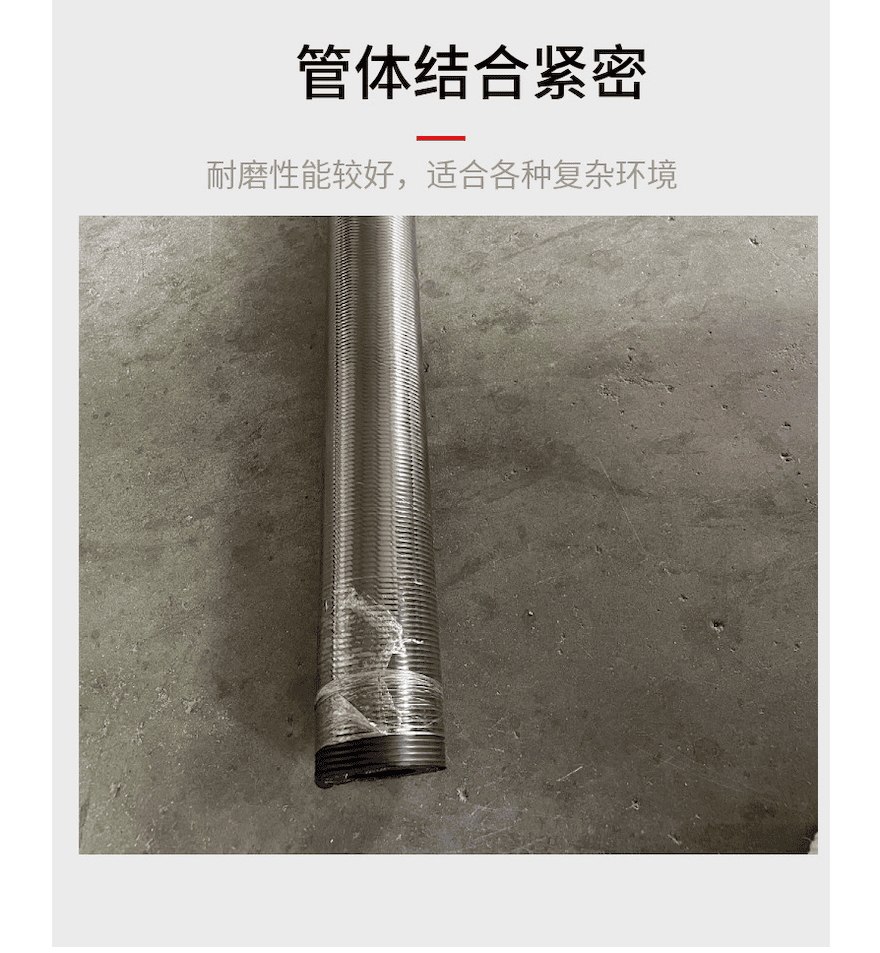

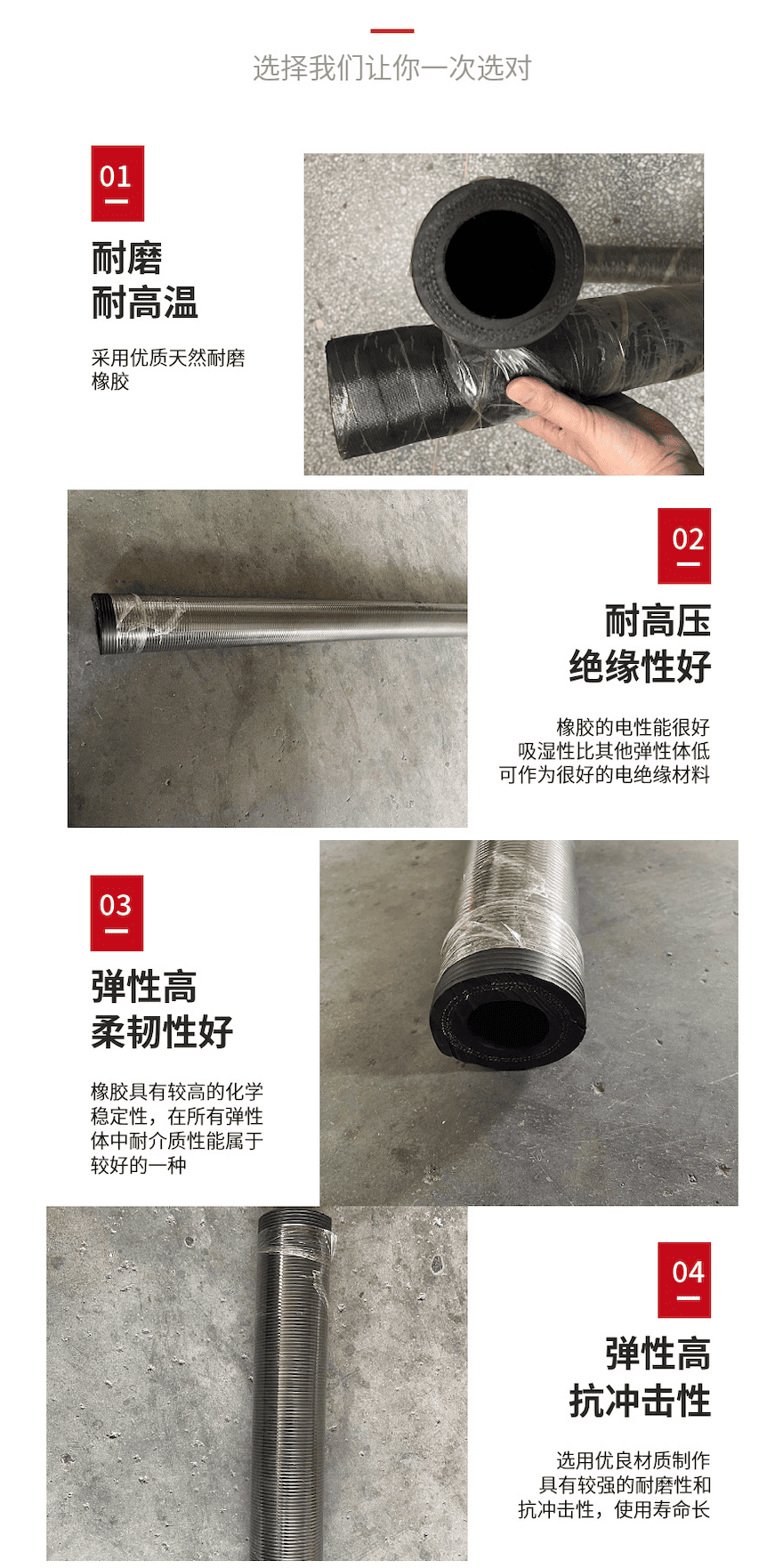

2. High Elasticity & Tear Resistance

Selected high-elastic rubber ensures the tube maintains its shape even under long-term compression, extending its lifespan.

3. Precise Flow Control

The peristaltic pumping mechanism allows for highly accurate flow control, suitable for precision filling and pharmaceutical applications.

4. No Cross-Contamination

The tubing only comes into contact with the fluid, preventing contamination commonly found in traditional pump systems, meeting hygiene standards in medical and food industries.

5. Easy Replacement & Maintenance

Quick tube replacement without extra tools minimizes downtime and improves work efficiency.

6. Compatible with Various Pumps

Works with different peristaltic pump brands and models, offering strong adaptability.

7. Excellent Pressure Resistance

Withstands high pressure and mechanical fatigue, ensuring stable fluid transfer even in demanding conditions.

8. Food & Medical Grade Certification

Compliant with FDA and USP Class VI standards, safe for sterile production environments in food and pharmaceutical applications.

9. Low Adsorption & Minimal Leaching

Smooth inner surface reduces fluid retention, preventing contamination and ensuring purity in laboratory and industrial processes.

Frequently Asked Questions (FAQ)

1. What is peristaltic pump tubing, and how does it work?

Peristaltic pump tubing is a specialized hose used in peristaltic pumps. The pump’s rollers compress the tubing, pushing fluid along the tube, ideal for contamination-free and high-precision fluid transfer.

2. Which industries use peristaltic pump tubing?

It is widely used in pharmaceuticals, laboratory analysis, food processing, chemical industries, and water treatment for handling high-purity, volatile, or corrosive liquids.

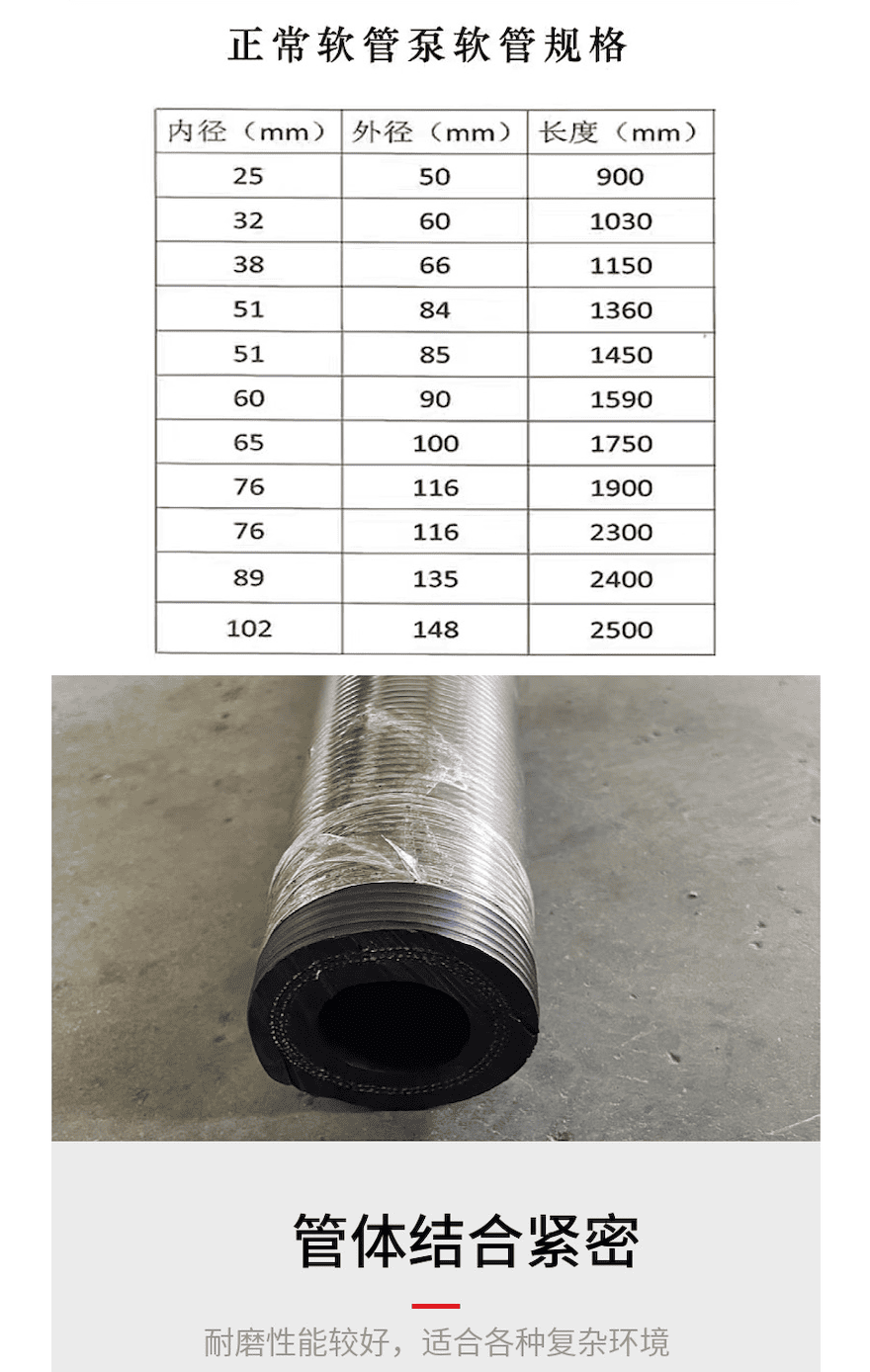

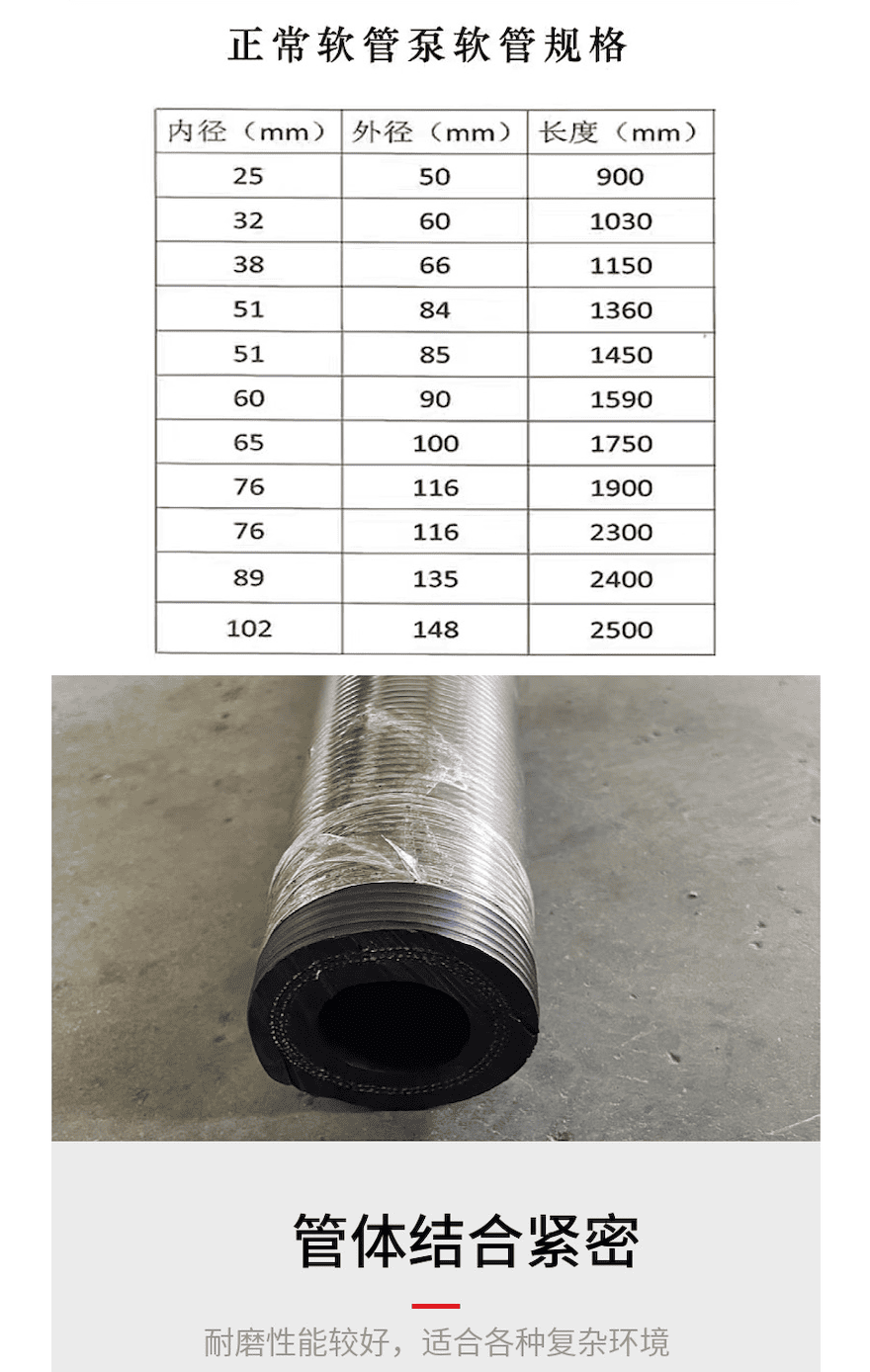

3. How to select the right peristaltic pump tubing?

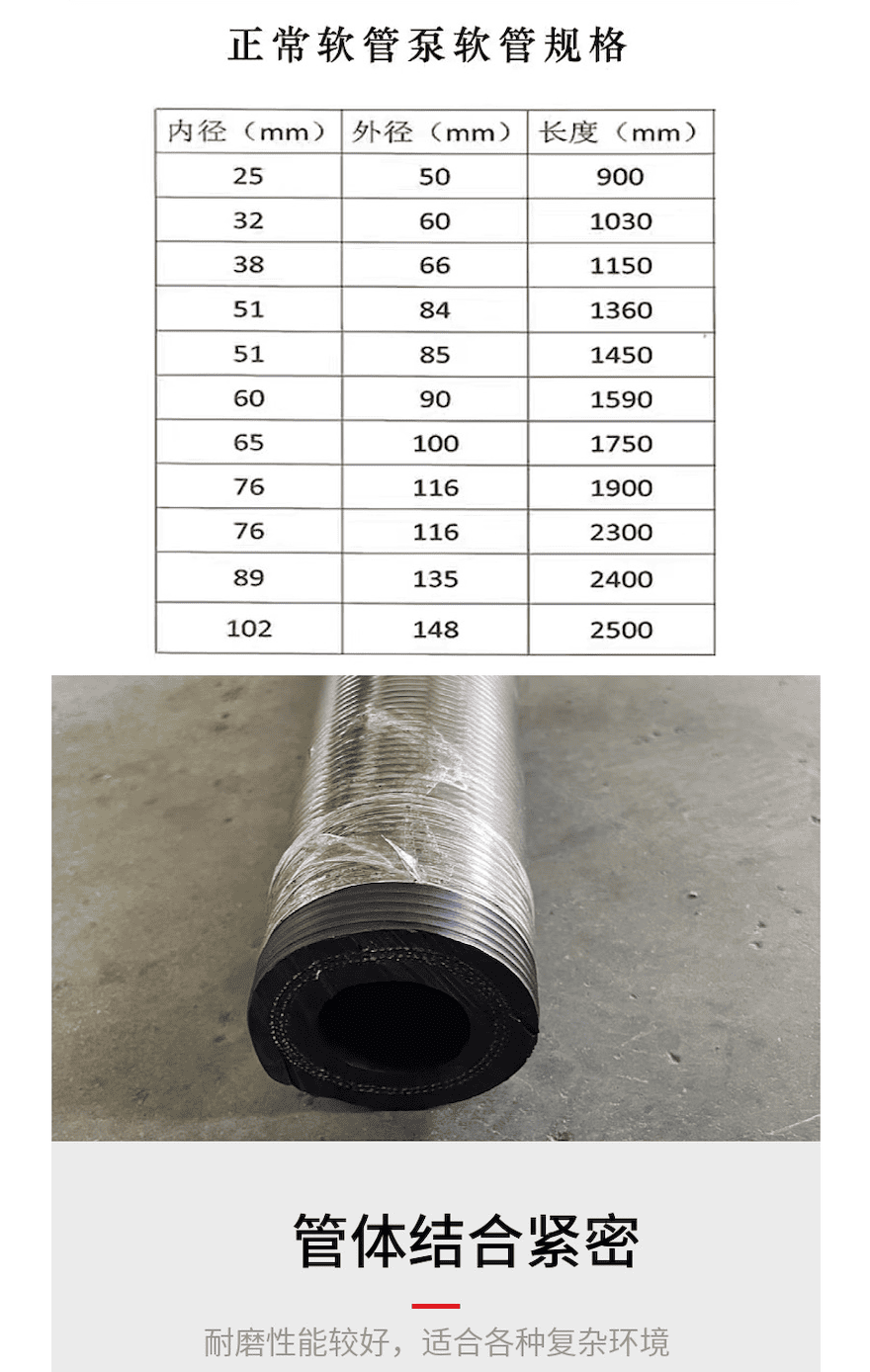

Choose the tubing based on the fluid’s chemical properties, temperature, pressure, and flow rate requirements to ensure optimal performance.

4. What is the replacement cycle for peristaltic pump tubing?

The replacement cycle depends on operating conditions, fluid type, and frequency of use. Regular inspections are recommended to replace worn tubing as per manufacturer guidelines.

5. Can peristaltic pump tubing withstand high temperatures?

Some high-temperature-resistant tubing materials can endure elevated temperatures, but the specific tolerance varies by material. Consult suppliers for detailed specifications.

Peristaltic pump tubing provides an efficient, durable, and safe solution for fluid transfer, ensuring precision and reliability across various industries.