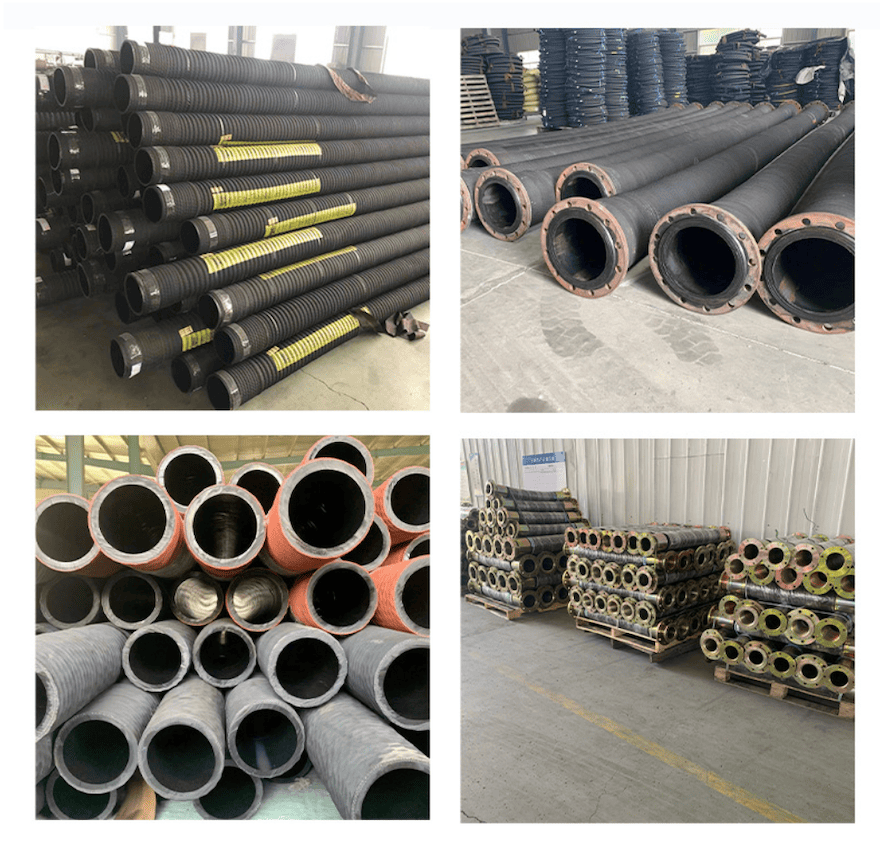

Suction Hose: Durable and Efficient Solution for Dredging and Mining Transportation

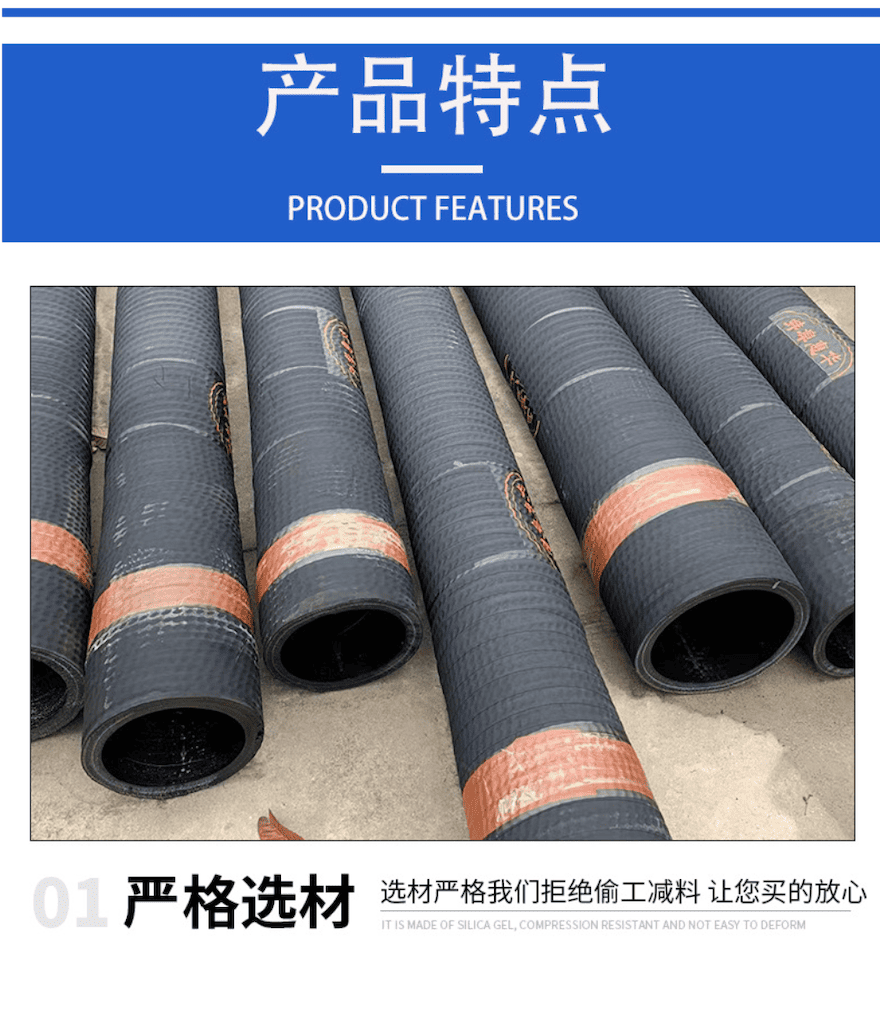

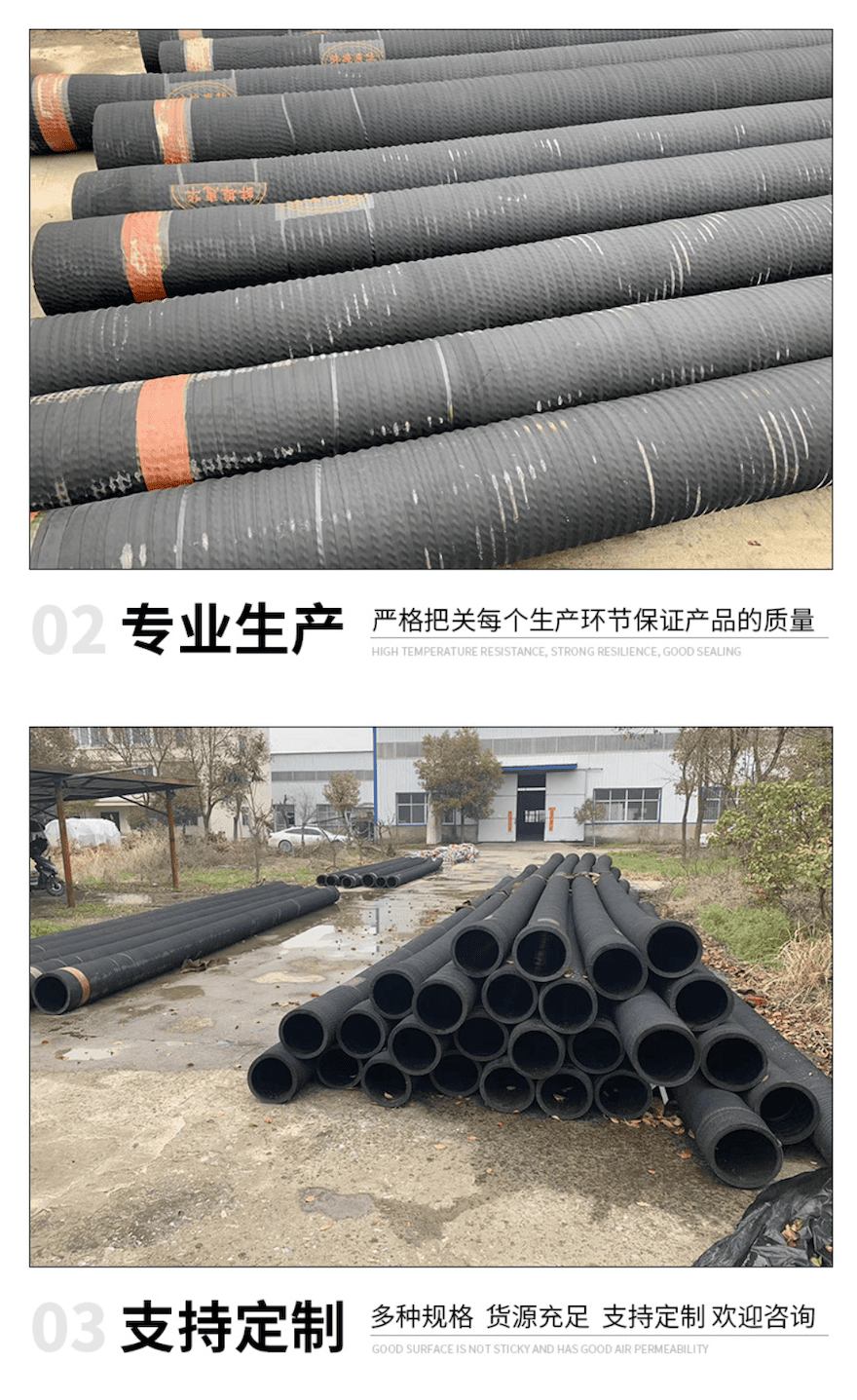

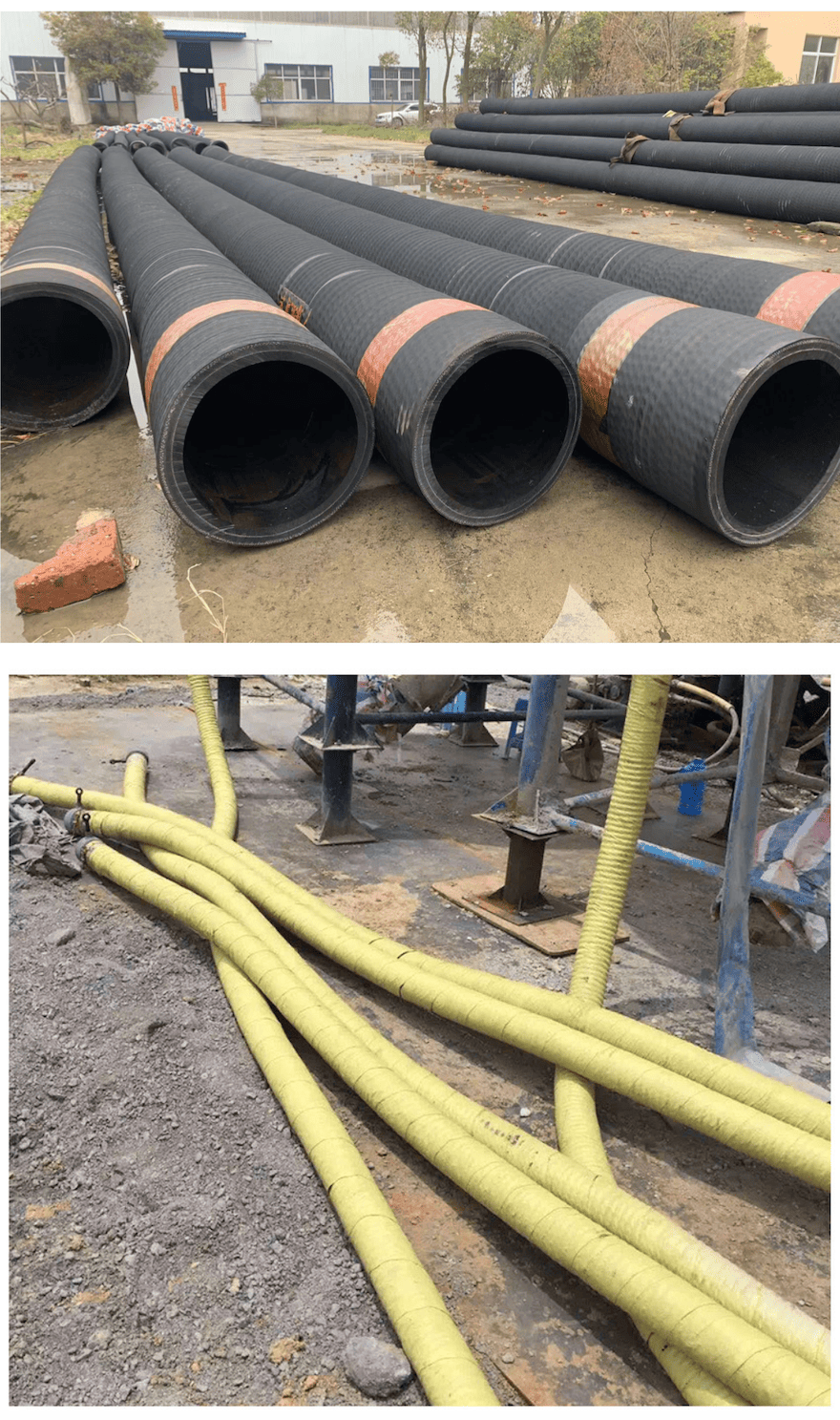

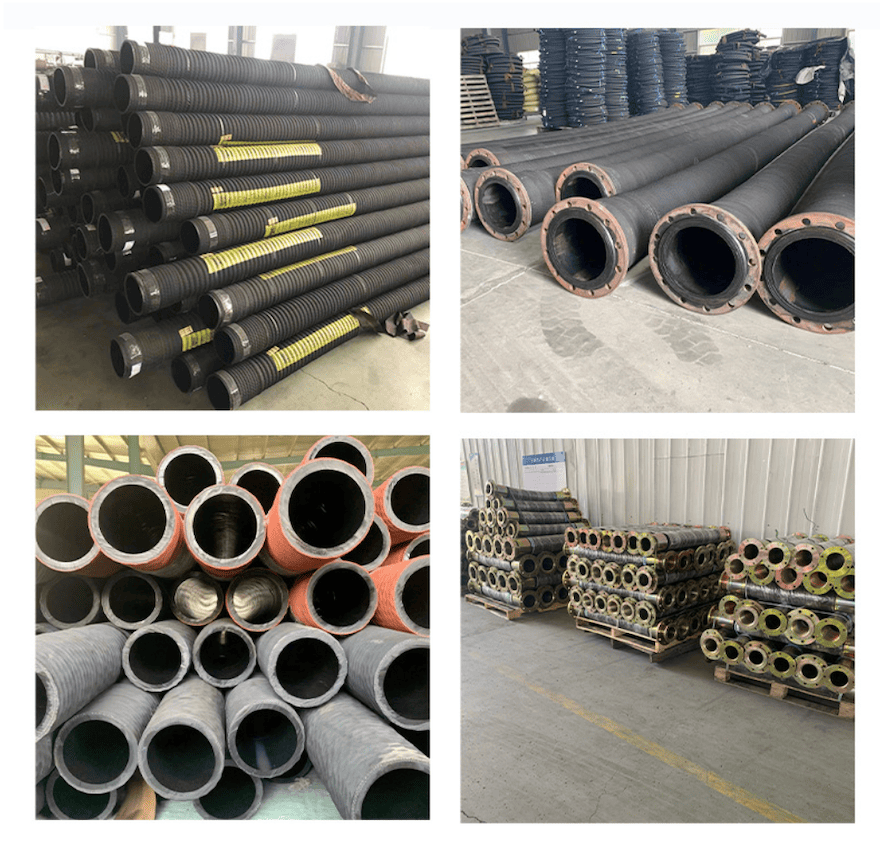

Suction hoses are widely used in dredging, mining transportation, and industrial cleaning. They feature wear resistance, corrosion resistance, and high-efficiency transport, making them ideal for river dredging, port maintenance, sand transportation, and other harsh conditions. Made from high-strength wear-resistant rubber, they ensure long service life and superior performance over long distances.

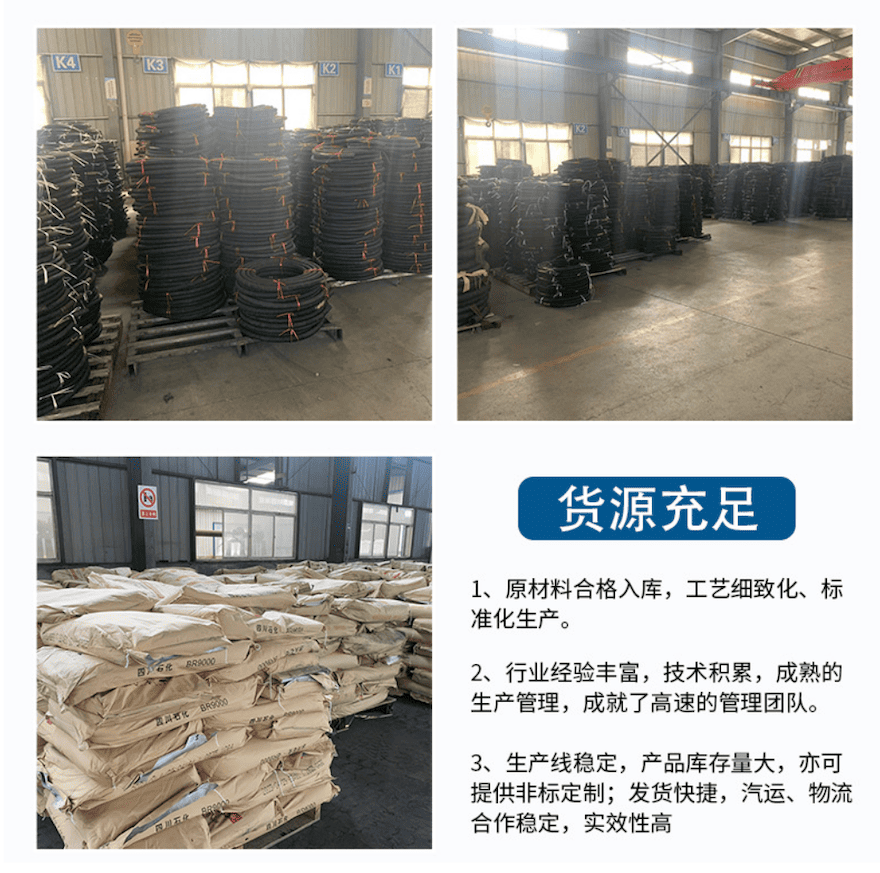

Advantages of High-Performance Suction Hose

• Wear-resistant: Made from high-durability rubber, extending service life and reducing replacement frequency.

• Corrosion-resistant: Suitable for seawater, sludge, and other complex media without damage over time.

• High strength: Reinforced framework structure ensures superior tensile strength and prevents rupture.

• Flexible: Bendable design adapts to different terrains and construction needs.

• High flow rate: Smooth inner wall reduces resistance, increasing efficiency.

• Pressure-resistant: Can withstand high working pressure for stable transportation.

• Easy maintenance: Simple installation and low maintenance cost improve overall efficiency.

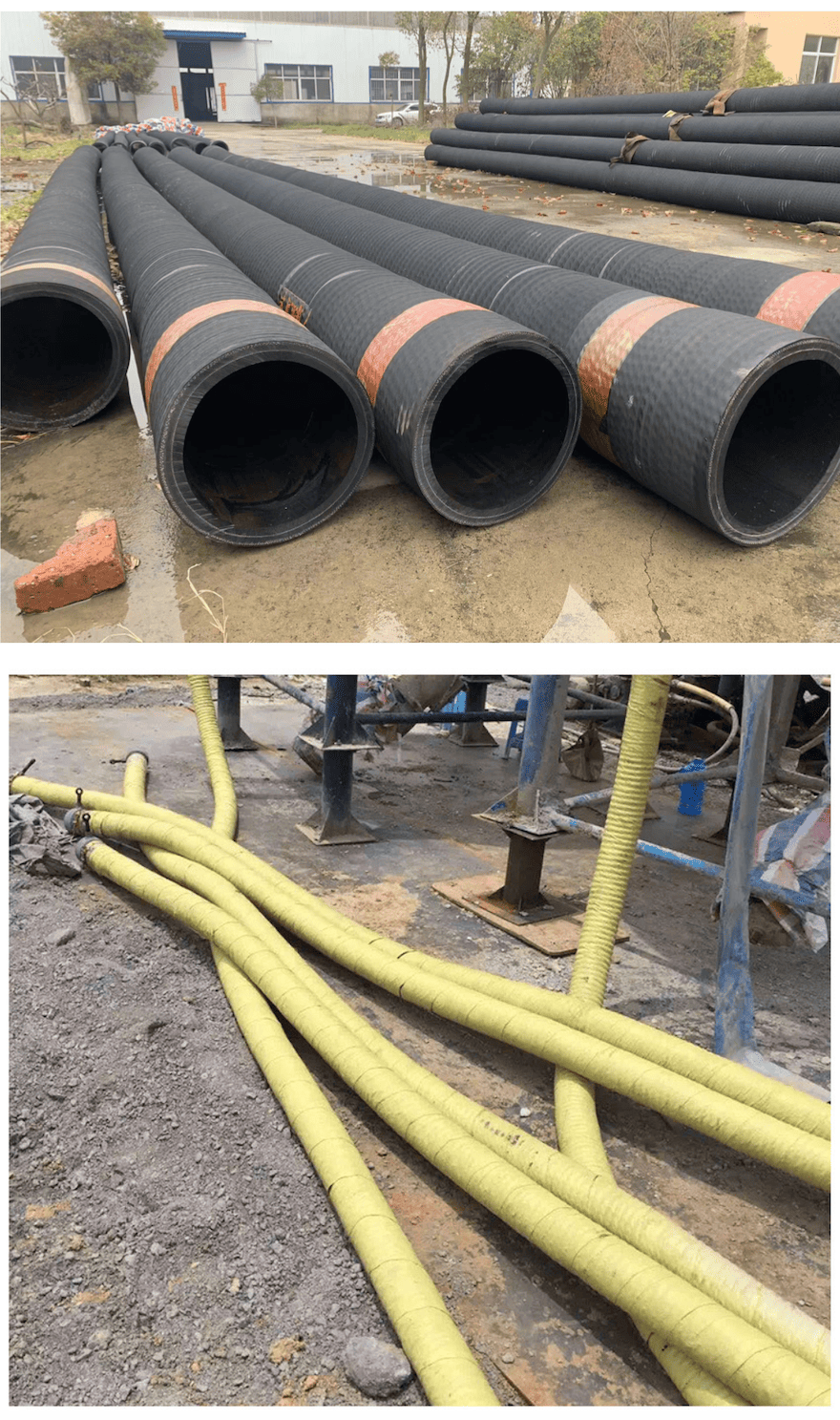

• Versatile compatibility: Connects with various pumps and transport equipment.

• Eco-friendly and safe: Non-toxic, compliant with environmental standards, suitable for diverse projects.

Applications of Suction Hose

Suction hoses are primarily used in river dredging, port clearing, mining, sand transportation, water conservancy projects, and industrial sludge transport. Their superior wear resistance and high transport efficiency make them essential in engineering, especially for offshore operations and harsh environments.

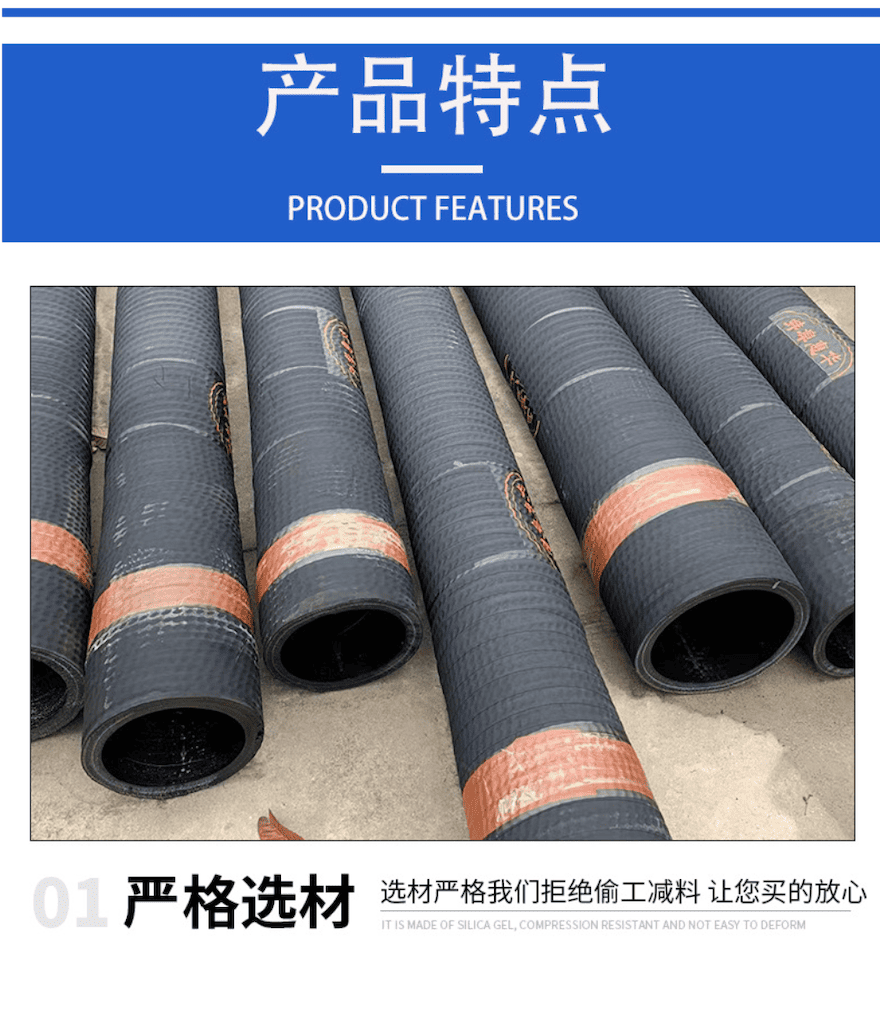

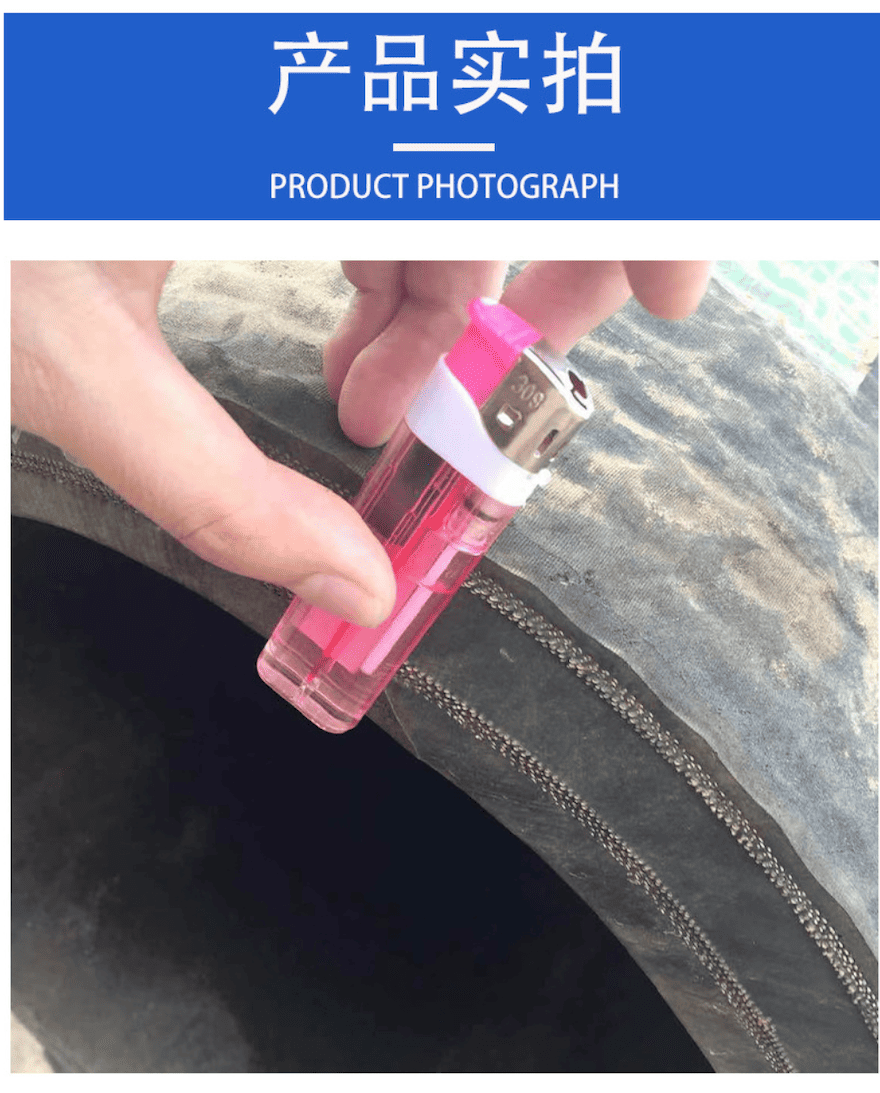

Key Factors for Selecting a Suction Hose

1. Diameter and Length: Choose the right size based on flow rate and working conditions.

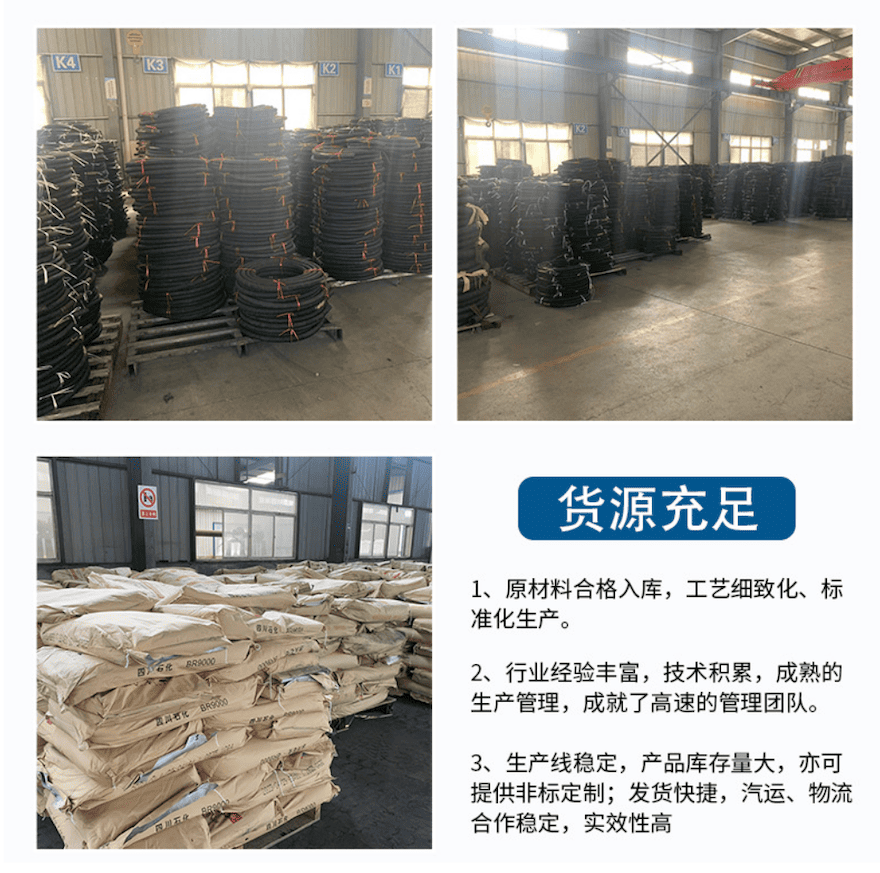

2. Material Durability: Different conditions require varying levels of wear resistance for cost-effective use.

3. Working Pressure: Ensure the hose can withstand operational pressure to avoid leaks and ruptures.

4. Connection Type: Select suitable flanges or quick connectors for secure and easy installation.

5. Environmental Adaptability: Choose hoses designed for different media (e.g., seawater, sludge, sand) to extend service life.

Common Questions (FAQ)

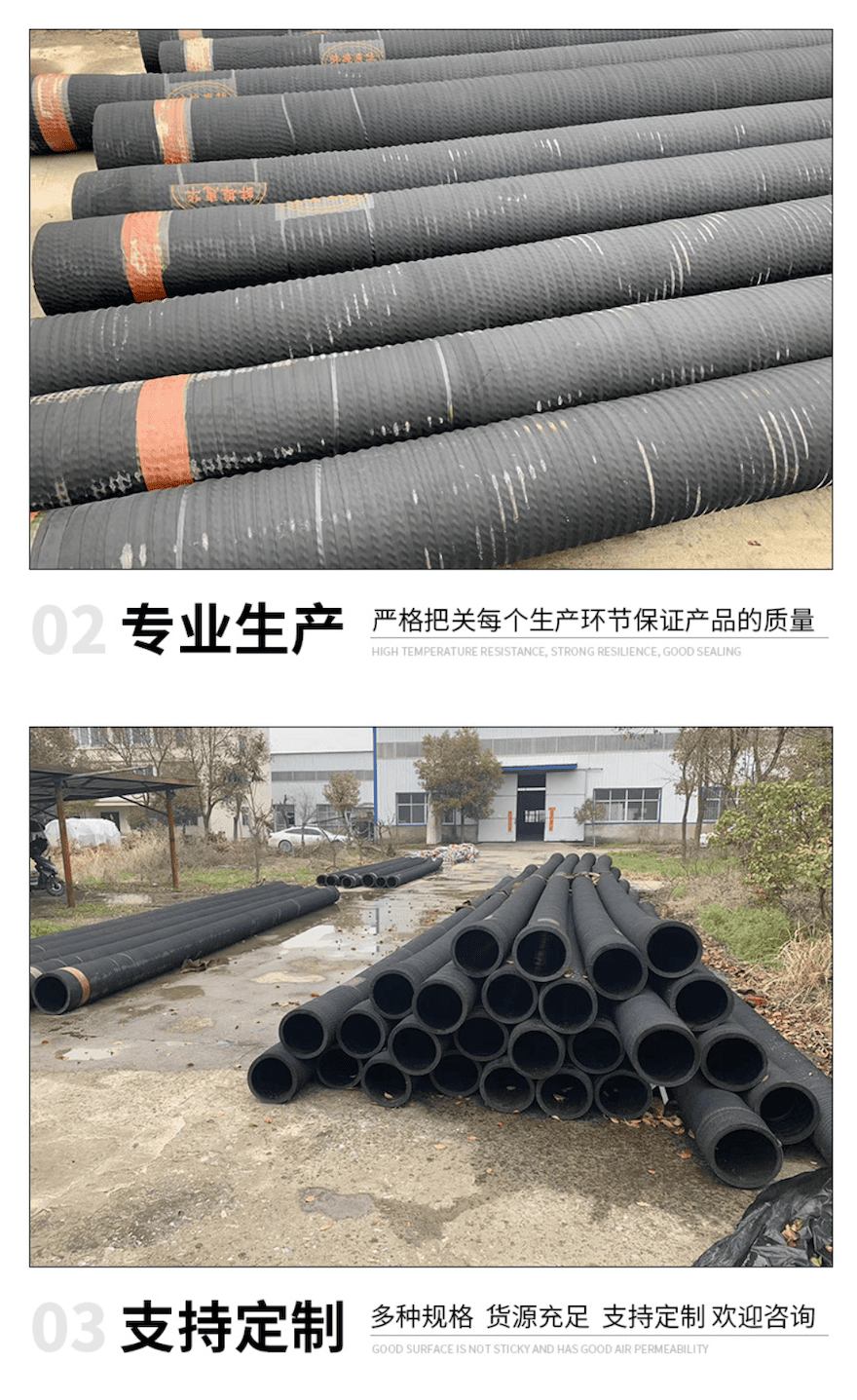

1. How long does a suction hose last?

Depending on the working environment and transported material, high-quality suction hoses can last 2-5 years with proper maintenance.

2. What types of pumps are compatible?

Suction hoses work with sand pumps, slurry pumps, centrifugal pumps, and other transport equipment.

3. What materials can be transported?

They are suitable for transporting mud, sand, cement slurry, ore particles, seawater, and other liquids.

4. How to choose the right suction hose?

Consider factors like material, flow rate, pressure resistance, and connection type based on your project.

5. How should suction hoses be maintained and stored?

After use, clean the interior, store in a cool, dry place, and avoid direct sunlight or heavy pressure to extend its service life.

#SuctionHose #WearResistantHose #DredgingPipeline #IndustrialTransport #MiningHose