Curtain Wire Wound Wind Pressure Hose Introduction

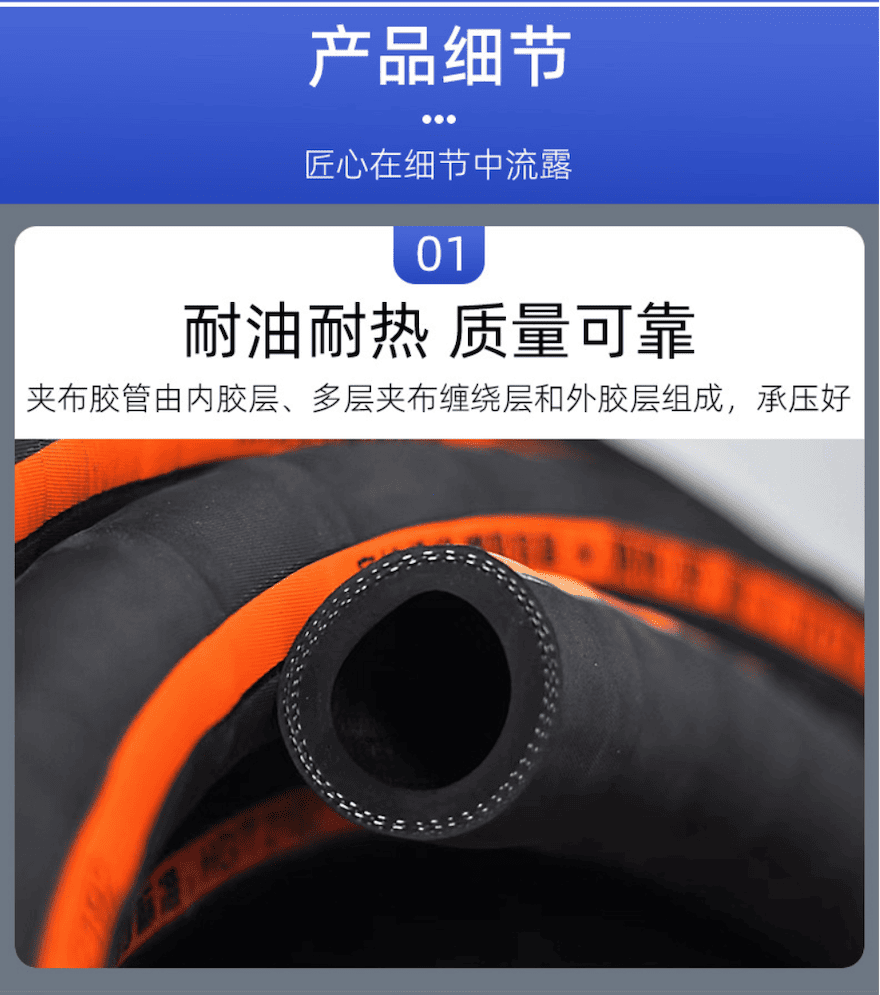

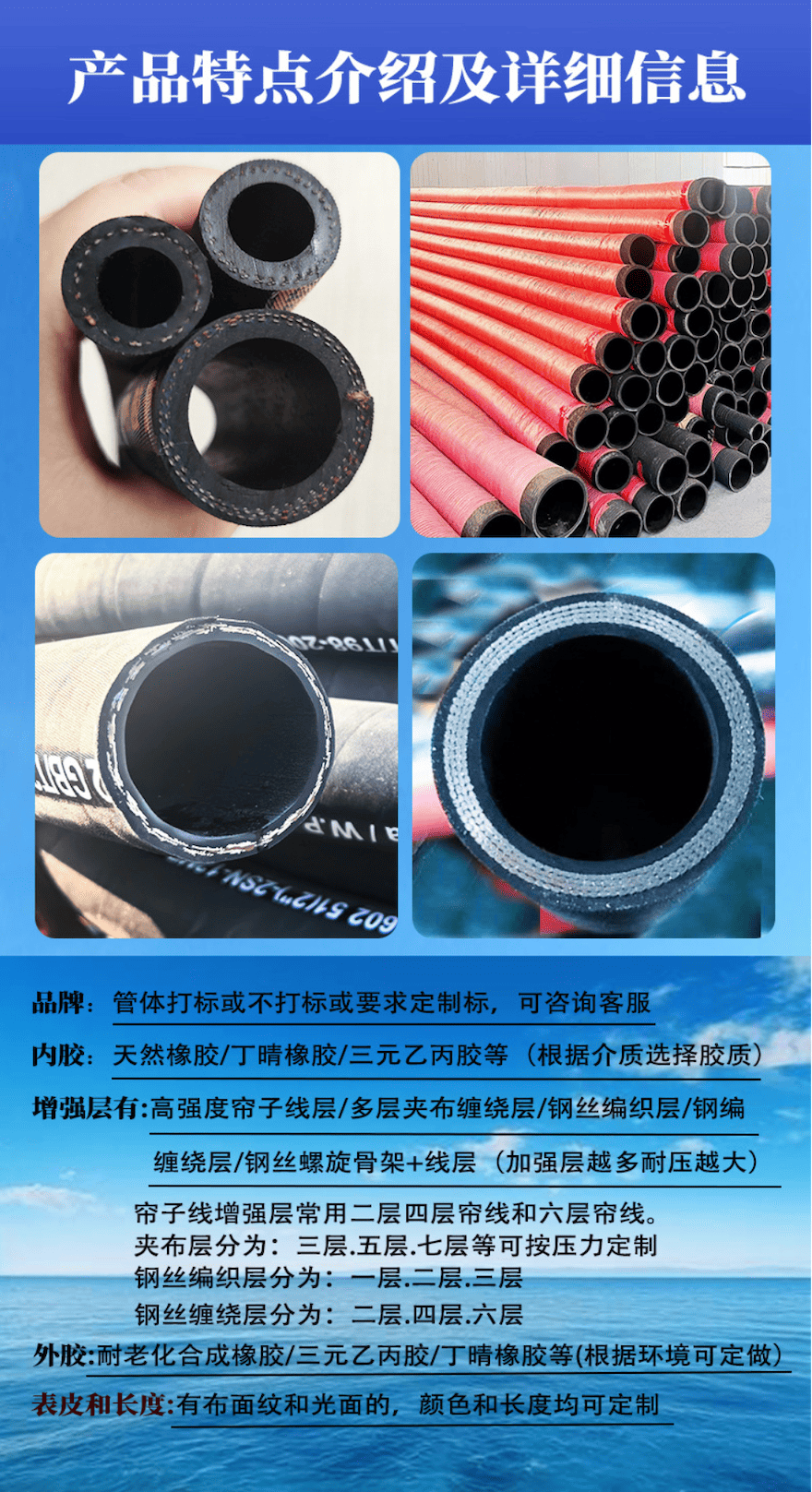

Curtain wire wound wind pressure hose is a high-strength hose designed to withstand high wind pressure and mechanical stress. It is widely used in construction, industrial, and various environments that require resistance to external forces. Its unique structure, consisting of inner and outer layers of materials reinforced with curtain wire, ensures excellent performance even in harsh environments. The hose performs excellently in high temperature, corrosion resistance, and pressure resistance, making it an indispensable component in modern industry.

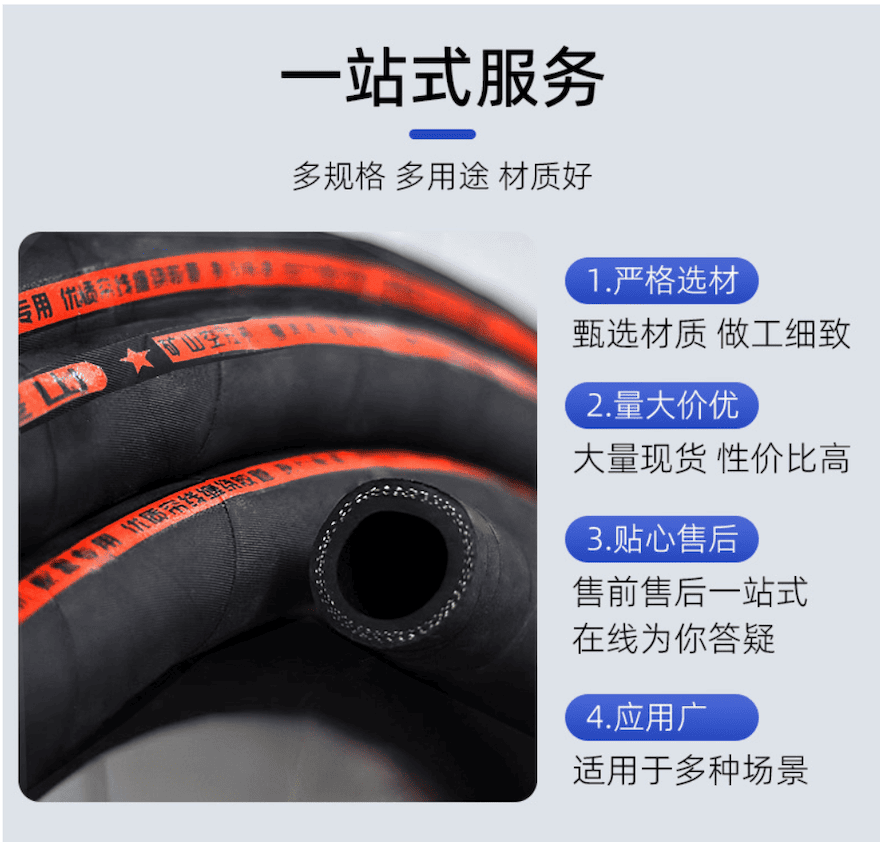

Features of Curtain Wire Wound Wind Pressure Hose

1.High strength, strong pressure resistance

2.High temperature resistance, adapts to extreme environments

3.Corrosion resistance, long service life

4.High-efficiency transmission, reduces energy loss

5.Meets various industrial equipment needs

6.Easy installation and maintenance

7.Excellent anti-aging performance

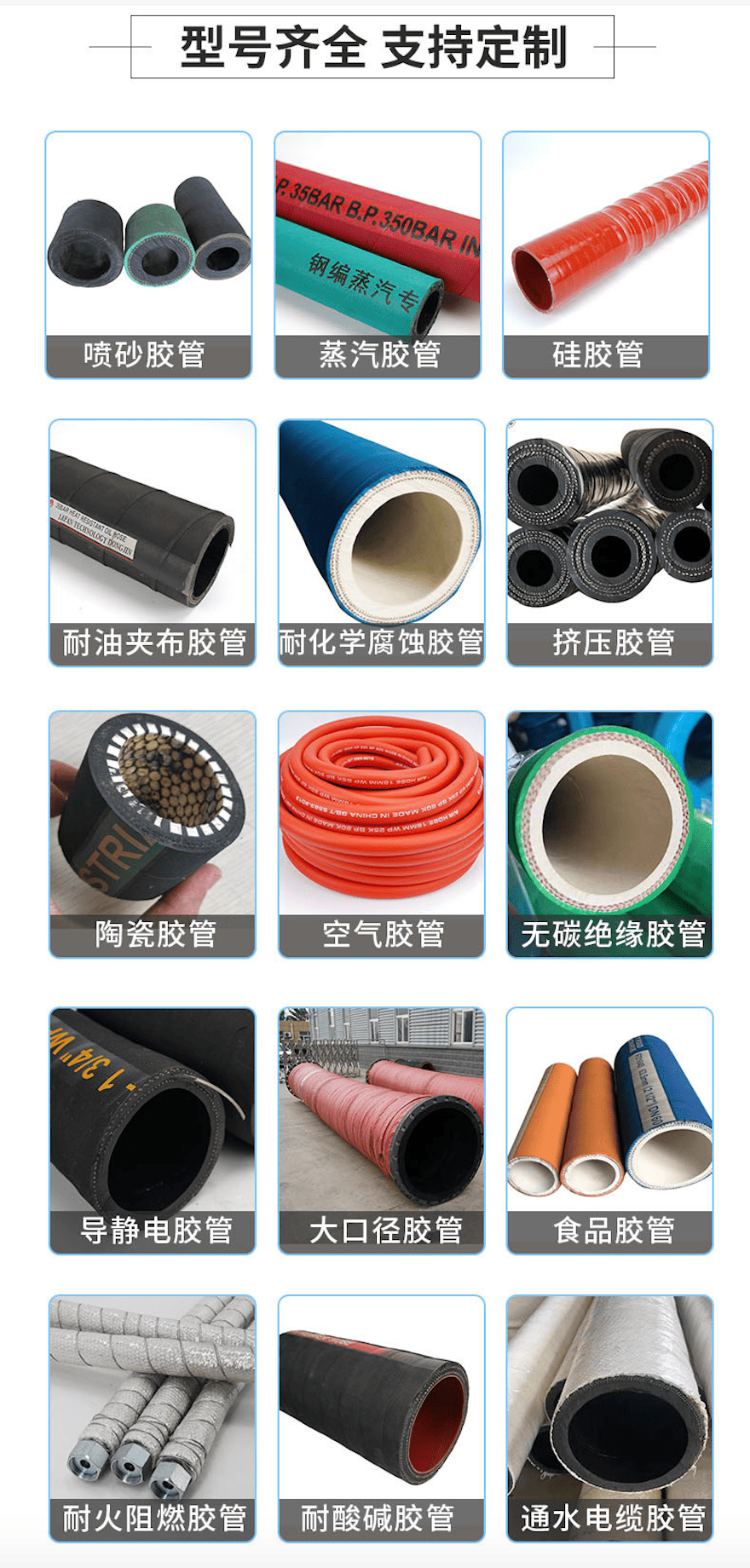

8.Customizable specifications according to needs

9.Multiple color options to suit different environments

Applications of Curtain Wire Wound Wind Pressure Hose

1.Widely used in construction projects

2.Essential in industrial equipment and machinery components

3.Fluid transmission in chemical plants

4.Pipeline systems in oil and gas industries

5.Fluid transmission in high-temperature environments

Market Outlook for Curtain Wire Wound Wind Pressure Hose

As industrialization continues to advance, the demand for curtain wire wound wind pressure hoses is increasing. Its applications across various industries, particularly in chemicals, oil, and construction, show strong market potential. For enterprises focusing on product quality and efficiency, curtain wire wound wind pressure hoses have become indispensable materials.

Frequently Asked Questions (FAQ)

1.What is the temperature tolerance of the curtain wire wound wind pressure hose?

It can withstand temperatures up to 200℃, making it suitable for most industrial environments.

2.Is this wind pressure hose resistant to corrosion?

Yes, the hose is made with corrosion-resistant materials and can be used in various chemical environments.

3.Can different sizes be customized?

Yes, it can be customized to different lengths and specifications according to customer requirements.

4.Which industries can use this hose?

It is suitable for use in construction, industrial, oil and gas, and chemical industries.

5.How is installation and maintenance performed?

Installation is simple, and maintenance involves regular checks on the connections to avoid prolonged exposure to harsh environments.