Food-Grade Silicone Tube: Safe and Durable Solution for the Food Industry

Food-grade silicone tubes are ideal for food processing, pharmaceuticals, beverages, and dairy industries. Made from high-quality food-grade silicone, these tubes are non-toxic, odorless, heat-resistant, and corrosion-resistant, offering excellent flexibility and aging resistance. They are widely used in food production lines, liquid transportation, and pharmaceutical applications.

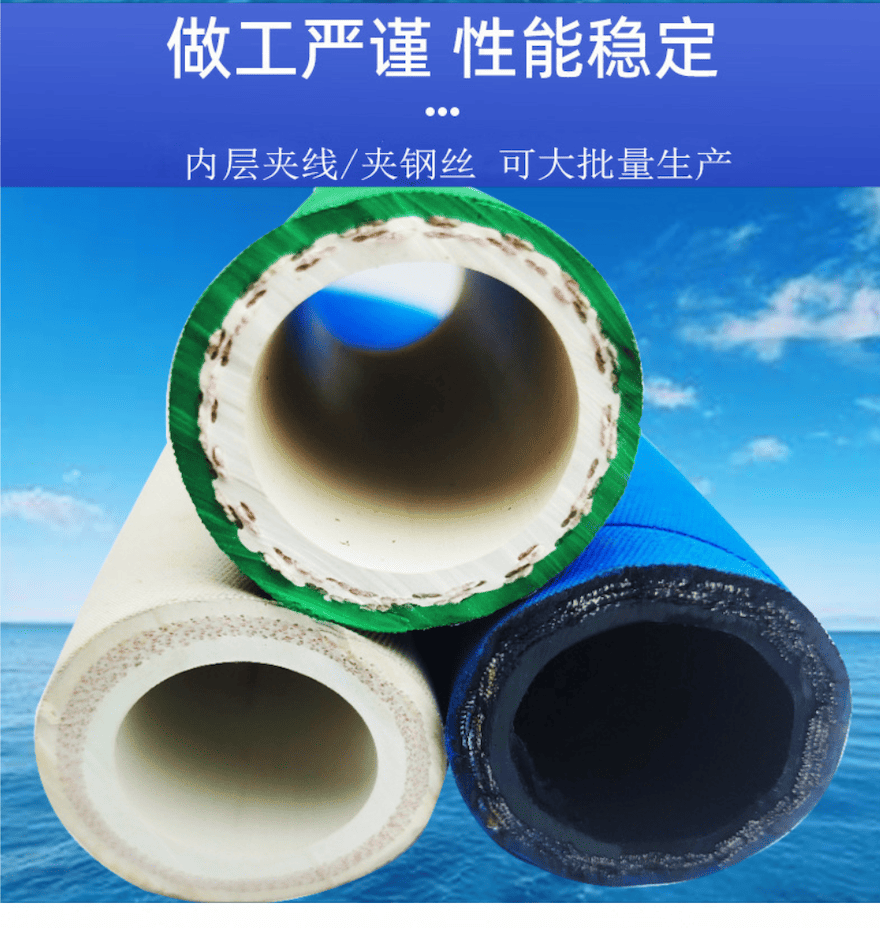

Main Features of Food-Grade Silicone Tube

1. High-Temperature Resistance: Withstands temperatures from -60°C to 200°C, suitable for high-temperature sterilization.

2. Food Safety Certification: Complies with FDA and LFGB standards for food contact safety.

3. Non-Toxic and Odorless: Does not release harmful substances, maintaining food quality.

4. Corrosion Resistance: Resistant to mild acids and alkalis, ideal for food and beverage transport.

5. High Transparency: Allows easy monitoring of liquid flow.

6. Excellent Flexibility: Remains flexible even in low temperatures, preventing breakage.

7. Easy to Clean and Maintain: Can be sterilized at high temperatures for long-term use.

8. Customizable: Available in various sizes, thicknesses, and hardness levels.

9. Wide Application: Suitable for transporting milk, juice, beer, pharmaceutical solutions, etc.

Applications of Food-Grade Silicone Tube

Food-grade silicone tubes are widely used in various industries:

• Food Processing: Safely transports milk, juice, beverages, and liquid seasonings.

• Pharmaceutical Industry: Suitable for sterile solutions and pharmaceutical liquids.

• Brewing Industry: Used in beer, wine, and beverage production, preventing contamination.

• Laboratory & Medical Equipment: Applied in biological research, chemical experiments, and medical device tubing.

How to Choose a High-Quality Food-Grade Silicone Tube?

Consider the following when selecting a food-grade silicone tube:

• Check Certification Standards: Ensure compliance with FDA, LFGB, or other safety certifications.

• Temperature Range: Choose a tube that withstands your production environment.

• Chemical Resistance: Ensure compatibility with the transported liquids.

• Transparency and Flexibility: Opt for high transparency for visual monitoring and flexibility for durability.

FAQ

1. Can food-grade silicone tubes be sterilized with high-temperature steam?

Yes, they are heat-resistant and suitable for steam sterilization.

2. How does a silicone tube compare to a PVC tube?

Silicone tubes offer better flexibility, heat resistance, and are free from plasticizers, making them safer.

3. Can food-grade silicone tubes transport acidic beverages?

Yes, they are resistant to mild acids and alkalis.

4. How to clean food-grade silicone tubes?

Rinse with warm water or use steam sterilization for hygiene.

5. Can food-grade silicone tubes be customized?

Yes, they can be tailored in size, thickness, and hardness for different applications.

Food-grade silicone tubes provide a safe, heat-resistant, and chemically stable solution for liquid transportation in the food and pharmaceutical industries. Contact us for more details or customization options.